The Chemical Safety Board issued a final report on a series of deadly combustible dust explosions in Tennessee. It highlights dust collection systems as the only way to prevent deadly combustible dust explosions. Recommends OSHA issue new comprehensive dust regulations within one year.

January 6th, 2012 Baghouse.com News | The Chemical Safety Board has issued its final report regarding a series of deadly industrial dust explosions accidents that occurred at the Hoeganaes powdered metals plant in Gallatin, Tennessee in 2011. The main cause of these three deadly explosions and fires that claimed five lives and injured many others was determined to be negligence regarding combustible dust hazards. The CSB further noted that a main factor in these accidents was the constant neglect of the plant’s dust collection system.

All three of the incidents occurred when large amounts of accumulated highly combustible iron dust where dispersed into the air and then ignited. The plant manufactures various metal powders for industrial use, the most produced of which is iron powder.

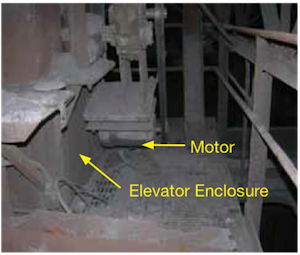

Picture of combustible dust accumulations near a bucket elevator that killed 2 workers when the dust was ignited by the motor.

The CSB investigation found that iron dust was present in high enough concentrations in the air to be clearly visible, and had accumulated on nearly all surfaces including elevated ledges, rafters, and other overhead spaces in amounts of 4 inches or greater. In addition the CSB clearly documented through photos and videos how dust handling equipment such as bucket elevators, conveyor belts, etc. were not adequately sealed, regularly leaking large amounts of dust into the air when in operation, and were not connected to the plant’s dust collection system. Additionally, plant workers told investigators that the dust collection system was regularly out of service due to maintenance.

Three Combustible Dust Incidents At One Plant In Six Months

The CSB investigation begin after the first of the three incidents occurred on January 31st, 2011 when fine iron dust particles coming from a broken bucket elevator were ignited while two maintenance personnel were performing repairs. The airborne particles were ignited by a spark from the bucket elevator’s electrical motor when it engaged. The resulting explosion and fire severely burned both workers, and eventually proved fatal for both men.

Just two months later, while the CSB was still conducting an investigation into the first incident, another flash fire occurred on March 29th when a maintenance worker used a hammer while reconnecting a gas line on the side of one of the plant’s furnaces. When he struck the side of the furnace with the hammer it lofted accumulated iron dust into the air, which then ignited, severely burning him, and causing him to fall from elevated working position further injuring him. According to CSB officials, “the build up of so much iron dust near a furnace with open flames and hot surfaces was a recipe for disaster. A fire was basically inevitable the moment the dust was dispersed into the air.”

March 29, 2011 Combustible dust fire in Gallatin, Te Hoeganaes powdered metals plant. The second of two serious dust fires/explosions in six months at the plant

Even with two such incidents within two months of each other, Hoeganaes management and its parent company still failed to take action to address the combustible dust safety issues at the Gallatin, Tennessee plant.

This failure proved to be catastrophic as just a few months later on May 27th when the an even deadlier third incident took place. Workers were repairing a corroded furnace pipe containing extremely flammable hydrogen gas caught fire when workers used a forklift to raise a metal floorplate to access the pipe. Workers has assumed the leaking gas was non-flammable nitrogen. After the initial explosion, the leaking gas continued to burn as a continues jet fire. The force of the initial explosion shook loose largeamounts of accumulated iron dust from overhead rafters. As the large plumes of iron dust fell they were ignited by the jet fire causing massive explosions further injuring workers and damaging the plant. One worker stated that so much iron dust was lofted into air, that even with a flashlight he was only able to see two to three feet in front of him as he tried to escape.

The aftermath of the third Hoeganaes combustible dust explosion in 2011. Notice the dislodged metal floor grating.

Evidence of Danger Present Well Before

All of these incidents were easily preventable. However plant management refused to take appropriate action to improve dust collection at the plant.

Even before the series of incidents, the plant had twice tested its dusts for combustibility. They ever were warned of the potential for a dust explosion after an insurance audit, which cited the potential for a such an accident due to the plant’s poor dust collection system policies, and housekeeping.

In addition to these warnings, the plant had firsthand knowledge of the combustibility hazards present in the plant, when on several occasions flash fires had occurred when workers performed maintenance using welding torches on dust covered conveyor belts. In fact the Gallatin Fire Department Hoeganaes facility in the last 12 years. These included one in June of 1999 where an iron dust fire in the baghouse lead to the hospitalization of one worker for smoke inhalation.

The CSB found that part of the core problem was that the plant, which was built over thirty years ago, was not designed according to good practice guidelines for combustible dust hazards, such as those set forth by the NFPA (National Fire Protection Association). “During its decades of operation, [the plant] was never redesigned to address the serious dust hazards” states CSB investigator Johnnie Banks.

Accumulated combustible iron dust on rafters at the Hoeganaes plant lead to several deaths when a series of dust fires and explosions occurred in 2011.

The plant has numerous flat elevated surfaces that easily accumulate large amounts of dust, and are difficult or impossible to clean with regularity. NFPA 484, which covers combustible metals safety, recommends that “floors elevated platforms, and gratings be designed to prevent dust accumulations and facilitate cleaning.” The same standard also requires that any machinery that emits combustible dust be connected to a dust collection system. Both of these recommendations were not followed by the Hoeganaes plant.

Many have asked how is it that these accidents were allowed to happen, even when plant management had all of these warnings and was in clear violation of best industry standards?

The city of Gallatin requires industrial facilities, including the Hoeganaes plant, to comply with the International Fire Code, which includes a brief chapter on combustible dust standards and references the more detailed NFPA standards. However the code does not require compliance with the more stringent NFPA standards. As a result the plant was not directly in violation of the International Fire Code that it was mandated to follow.

CSB Recommendations Based On Its Investigation

As a result of the CSB investigation, the CSB has proposed several actions be taken to reduce the risk of more combustible dust incidents from occurring elsewhere.

First, the CSB recommended that the International Code Counsel “revise the International Fire Code to mandate compliance with the combustible dust safety standards set forth by the NFPA.”

Secondly, in its 2006 report on the dangers of combustible dust hazards in industry, the CSB recommended that OSHA (Occupational Health and Safety Administration) issue a comprehensive combustible dust safety standard for general industry. As a result in 2007 OSHA instituted a national emphasis program for combustible dust, with the stated goal of eventually issuing a comprehensive combustible dust standard in the near future. In 2009 OSHA announced that it would begin the rule making process for combustible dust hazards. However, in 2011 at the time of these accidents, no standard had yet been proposed, or completed.

As a result, in its final report on the incidents, the CSB recommended that OSHA issue its long awaited combustible dust standards “within one year”, and that the standard include combustible iron and steel powders. In the meantime, the CSB recommended that plants that manufacture steel and iron powders be included in the national emphasis program. for combustible dust.

What This Means For Facilities With Combustible Dust Hazards

The continued loss of life due to combustible dust hazards is no longer being ignored by the CSB, OSHA, or other governmental agencies. The only way to prevent the loss of additional lives is for industry to begin following best industry standards as set forth by the NFPA and eventually the comprehensive standard by OSHA.

In the meantime, plant mangers and operators can educate themselves on the dangers of combustible dusts by reviewing educational articles on the subject such as those published here on Baghouse.com (http://www.baghouse.com/2011/01/19/the-potential-for-dust-explosions-in-dust-collection-systems/). They can also seek the assistance of experts in the dust collection industry to identify areas where improvement can be made, and make suggestions of ways to increase dust collection efficiency at their facilities.

For more information about the dangers of combustible dusts, please see the following links:

The CSB video reports on the Hoeganes incidents:

The following LinkedIn groups work specifically to raise awareness of combustible dust hazards, and lobby for comprehensive standards for general industry:

http://www.linkedin.com/groups?gid=1184577&goback=%2Egmp_1184577

http://www.linkedin.com/groupRegistration?gid=2076996&csrfToken=ajax%3A2562522142432018780&goback=%2Eanb_2076996_*2

About the Author

| Dominick DalSanto is an Author & Environmental Technologies Expert, specializing in Dust Collection Systems. With nearly a decade of hands-on working experience in the industry, Dominick’s knowledge of the industry goes beyond a mere classroom education. He is currently serving as Online Marketing Director & Content Manager at Baghouse.com. His articles have been published not only on Baghouse.com , but also on other industry related blogs and sites. In his spare time, Dominick writes about travel and life abroad for various travel sites and blogs.