https://www.baghouse.com/wp-content/uploads/2011/09/post33.png

643

1237

dominickdalsanto

https://www.baghouse.com/wp-content/uploads/2018/03/BH-Logo-Alt-01.png

dominickdalsanto2011-09-10 11:57:522023-12-11 23:45:54Industrial Air Permits & Your Dust Collection System – Unfair & Confusing Enforcement

https://www.baghouse.com/wp-content/uploads/2011/09/post33.png

643

1237

dominickdalsanto

https://www.baghouse.com/wp-content/uploads/2018/03/BH-Logo-Alt-01.png

dominickdalsanto2011-09-10 11:57:522023-12-11 23:45:54Industrial Air Permits & Your Dust Collection System – Unfair & Confusing EnforcementCompetitive companies can’t afford to make mistakes. With so many different approaches to Dust Collection, you need expertise you can trust. We will help you find the dust collection system that best fits your needs and at a price that will fit your budget.

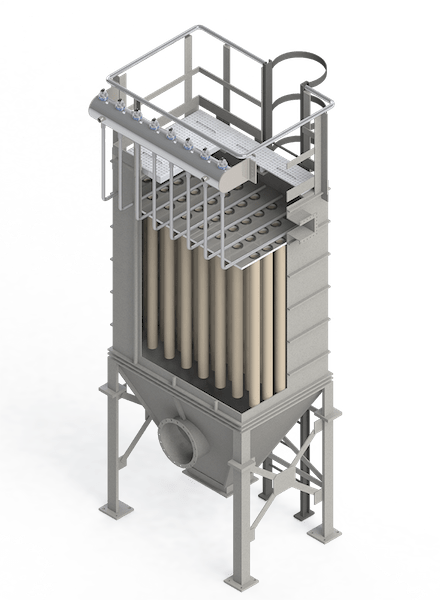

Baghouses with Filter Bag Collectors – These collectors are the most widely employed, and with good reason. Fabric filter collectors offer the widest range of applications, and if operated and maintained properly, will result in the best overall performance. Ideal for the use of wide range of industries including power Generation, industrial processing (pharmaceutical, mineral, chemical, rubber, food, etc) woodworking/milling, ferrous and nonferrous production, smelting and processing, cement production, industrial boilers, biomass boilers, etc.

Cartridge Collectors – Ideally suited for applications with light or fine dusts and low to moderate grain loading levels. Certain dusts require minimal flexing of the media during the cleaning process; thus, cartridge collectors will perform satisfactory in certain applications. Standard cartridges can have 350 sq/ft or more of filter media each, which enables these units to handle large airflows within a much smaller unit than a comparable baghouse. Higher temperatures or abrasive dusts and heavy dust loading applications can overwhelm and wear down the lighter duty units and cartridges however. Common uses include sandblasting, food processing, bulk materials handling, welding fumes, laser and plasma cutter fumes, metalworking, powder coating, graphite, pharmaceutical and fine chemical powders.

Cyclone Collectors – These are often employed as a initial stage collector or prefilter to lighten heavy dusts loads before being sent to a primary stage fabric collector such as a baghouse or cartridge collector. By removing coarse particles from the gas stream, and allowing later stage fabric collectors to solely remove finer particles, this increases the service life of fabric Collectors and their filters. This design works by creating a vortex in the airstream within an enclosure, similar to water going down a drain. As the airstream is spun around the collector, the particles strike the wall and fall into the hopper below.