https://www.baghouse.com/wp-content/uploads/2020/01/industrial_dust_powder_1.jpg

750

1000

BH

https://www.baghouse.com/wp-content/uploads/2018/03/BH-Logo-Alt-01.png

BH2019-12-26 13:00:002020-01-29 18:40:25Wood Products Firm Fined $114K for Combustible Dust

https://www.baghouse.com/wp-content/uploads/2020/01/industrial_dust_powder_1.jpg

750

1000

BH

https://www.baghouse.com/wp-content/uploads/2018/03/BH-Logo-Alt-01.png

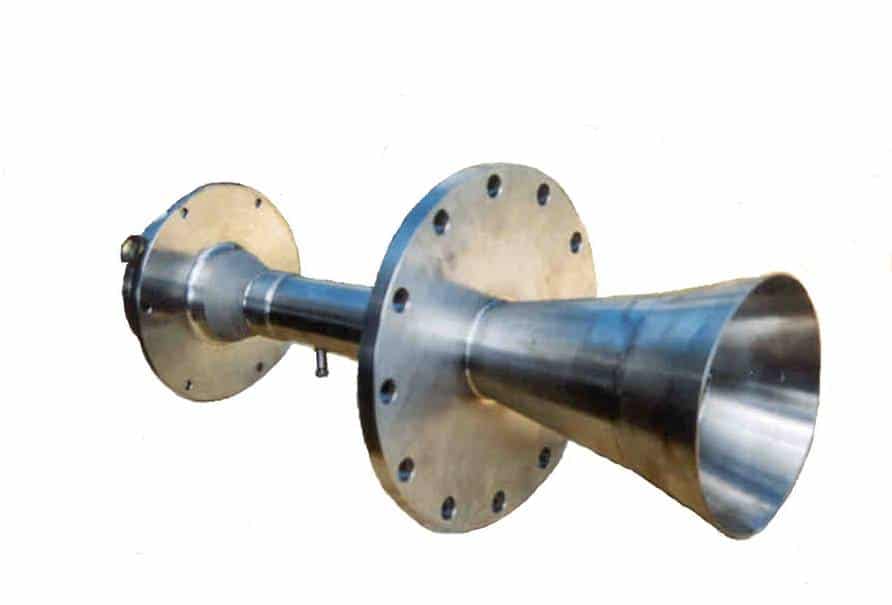

BH2019-12-26 13:00:002020-01-29 18:40:25Wood Products Firm Fined $114K for Combustible DustSonic Horns

In certain situations, the normal cleaning mechanism (Pulse-Jet, Shaker, or Reverse-Air) has difficulty achieving 100% efficiency. This may be due to characteristics of the dust being collected in the baghouse. Or it may be simply that due to design limitations that specific areas accumulate large amounts of dust.

This is where you might choose to employ a Sonic Horn in order to supplement the normal cleaning system. Sonic horns add cleaning energy with a minimum of modifications to install and operate. And the cost is minimal for the cleaning energy gained, particularly as compared to other modifications of the equipment already in use.

How Sonic Horns Work

This equipment functions by producing high intensity sound waves that vibrate the accumulated dust fluidizing the dust causing it to fall off the surfaces where it has collected. Only the target dusts and compounds are affected, Fabric filter media and metal surfaces and structures are not affected nor damaged in any way. Consequently, there is no need for structure support or special fabric considerations.

Some common applications for this technology include:

- Fan Blades

- Ductwork

- Filter Bags

- Distribution Plates

- Baghouse Hopper Walls

Benefits

By utilizing this technology to remove accumulated dusts, you can reduce system downtime, and maintenance that are often caused by plugged hoppers, fouled fan systems, repairs of shaker mechanism, short bag life or poor bag cleaning, and general maintenance costs.

For more information about how Baghouse.com Sonic Horns can help you to improve your Baghouse efficiency, please Contact one of our representatives today!