What is a Cartridge Dust Collector

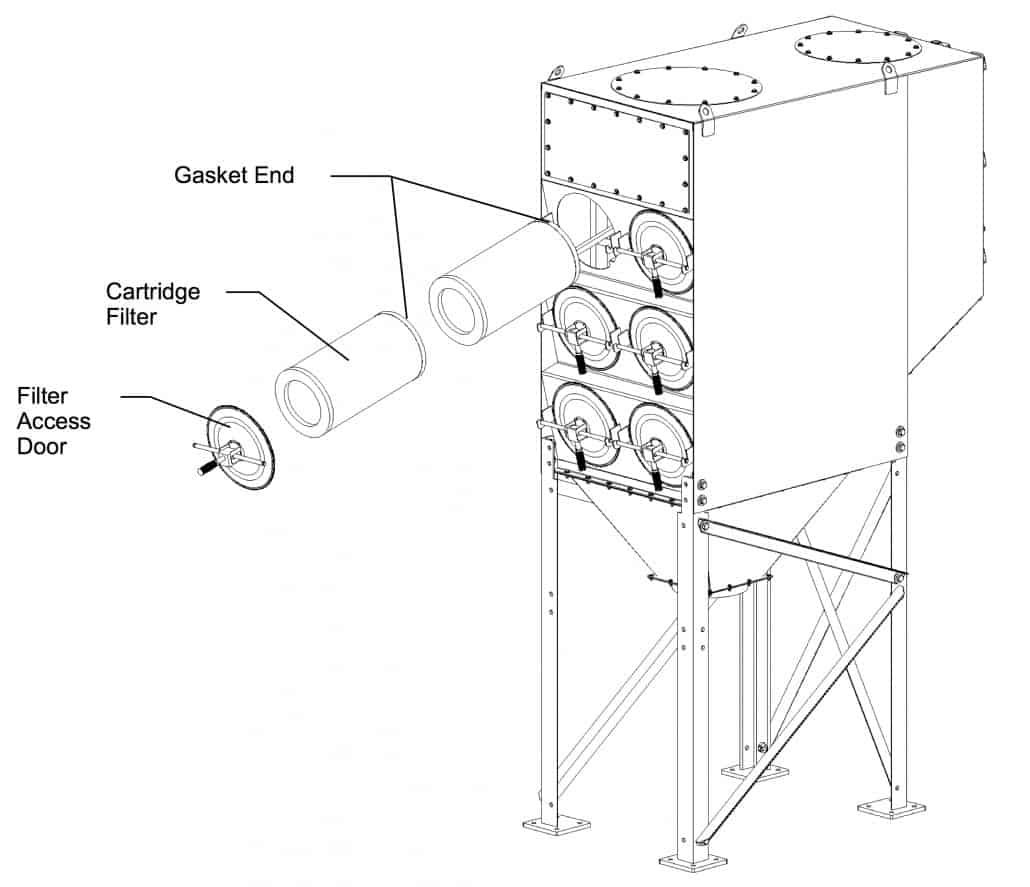

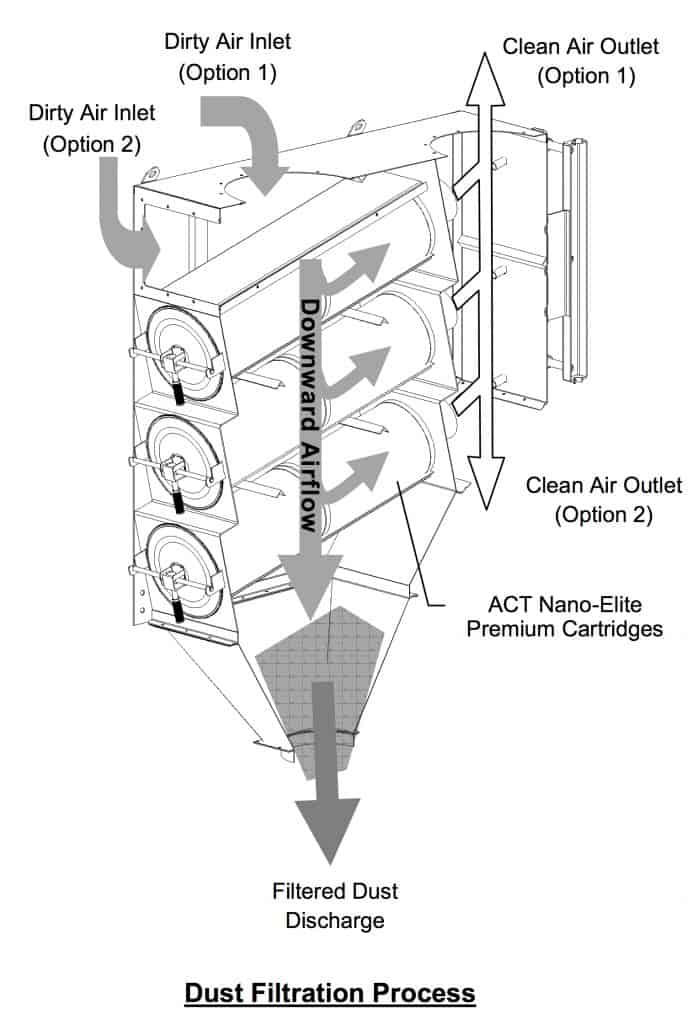

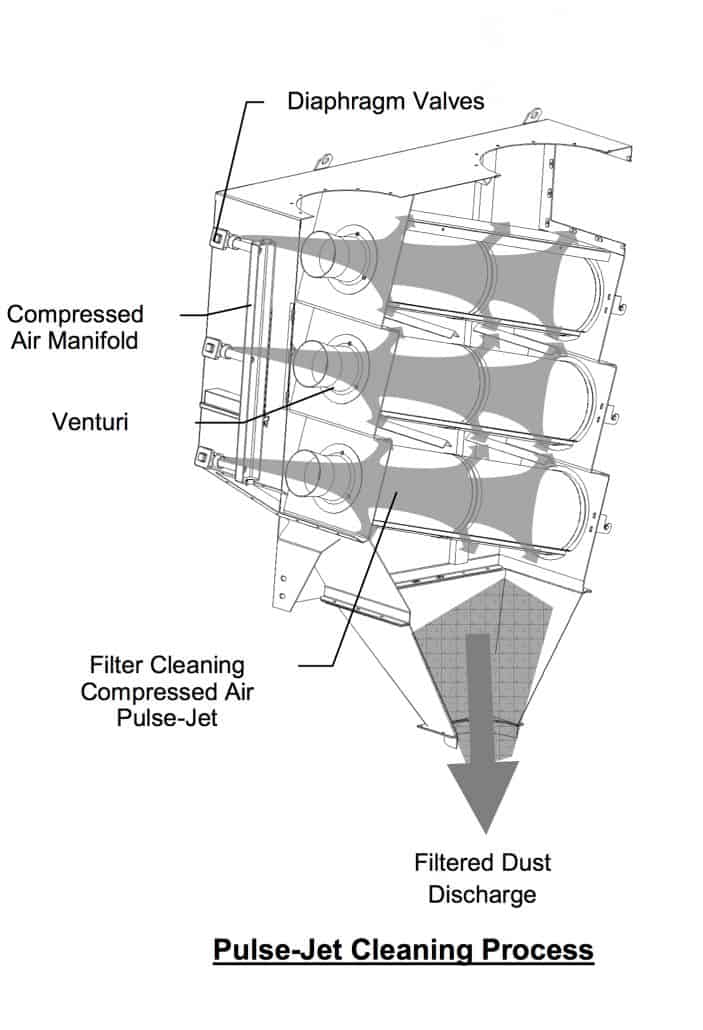

A cartridge dust collector is a very common style of dust collector used across many industries. Instead of filter bags, it uses cartridges that are usually cylindrical or oval shaped and open on one or both ends lined with a pleated nonwoven filtering media. Once installed, one end of the cartridge is sealed off and the open end is used for the clean exhaust. Similar to a baghouse, the gas stream is forced through the outside of the cartridge to the inside where it then exits back into the system. The collector cleans the cartridges using a jet of compressed air blown back into the cartridge that dislodges the built up dust causing it to fall into the hopper below.

What Applications Should Use Cartridge Collectors Instead of Baghouses?

Generally cartridge collectors work well with low to moderate temperature applications with very fine and light dusts and that have light to moderate dust loading such as powder coating, metalworking, bulk material handling, sanding, laser/plasma cutting, blasting, fume collection, pharmaceutical manufacturing, thermal spray, welding, and certain woodworking processes among others. Even some heavy loading applications can use cartridges is the dust releases easily and temperature and moisture is not a problem.

In these applications, cartridge collectors offer a more economical option compared to traditional baghouse designs. They provide a much greater airflow in a smaller sized unit, and use fewer filters (average of 350 ft/2 of filter area per cartridge vs. less than 20 ft/2 for traditional pulse jet filter bags), which reduces the cost of the unit significantly. The smaller footprint allows for easier installation and take up less space. Maintenance personnel can also replace cartridges much more easily than filter bags while also reducing physical contact with the collected dust and without entering any confined spaces, which reduces downtime required for changeouts and safety considerations for maintenance. Additionally, spunbond and nano fiber filter media commonly used in cartridges provides excellent filtration efficiency for their intended applications with some filters carrying up to MERV 16 rating.

Advantages of Cartridge Collectors by Baghouse.com

- Especially effective at collecting very fine and light dusts

- More airflow in a smaller unit compared to baghouses

- Smaller footprint and simpler maintenance

- Quickly and easily change cartridges without entering confined space or contact with hazardous materials

- Lower initial cost and lower on-going maintenance costs

- Easily fitted with high efficiency filters (MERV 16) for maximum collection efficiency

Common Dust Collection Applications For Cartridge Collectors

- Blasting

- Bulk Materials

- Ceramics

- Chemical Processing

- Fine Powder

- Food Processing

- Glass

- Laser Cutting

- Metalworking – Aftermarket Retrofits

- Metalworking – Forging and Recycling

- Metalworking – Machining

- Metalworking – Other

- Metalworking – Sanding, Grinding and Buffing

- Mining

- Paper Scrap

- Powder Coating

- Pharmaceutical

- Plasma Cutting

- Recycling

- Rubber Grinding

- Sanding, Grinding and Sawing

- Sand Blasting

- Thermal Spray

- Welding – Ambient Fume

- Welding – Source Capture

- Woodworking

| Tailored to Meet Your Needs

Baghouse.com’s line of cartridge collectors comes in various sizes to fit all size applications. We offer several standard features and options so that each unit perfectly fits your application.

Standard Features

- Welded, heavy duty construction with 7 gauge and 10 gauge carbon steel

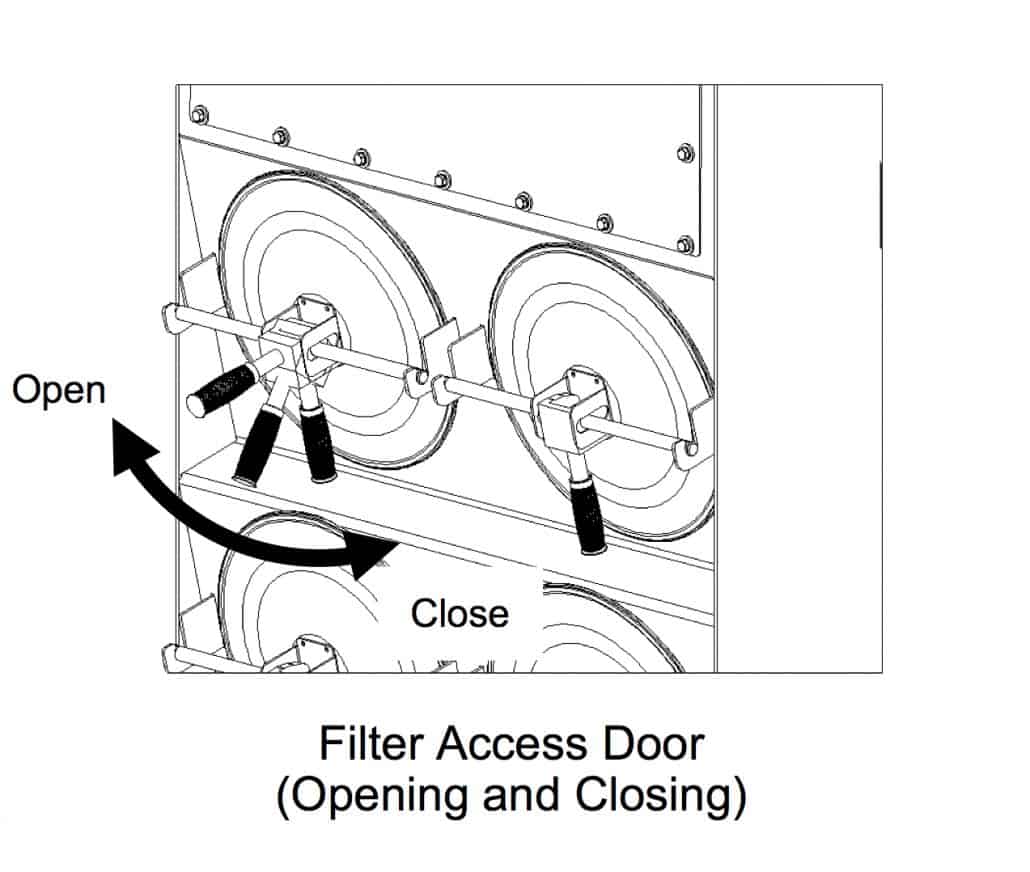

- Quick-Release door latches for easy filter cartridge access

- Nanofiber elite MERV 15 cartridges with 250 sq/ft of fabric area per cartridge

- Downflow technology improves filter cleaning, dust release and minimizes dust reentrainment

- Welded lifting lugs for easy installation

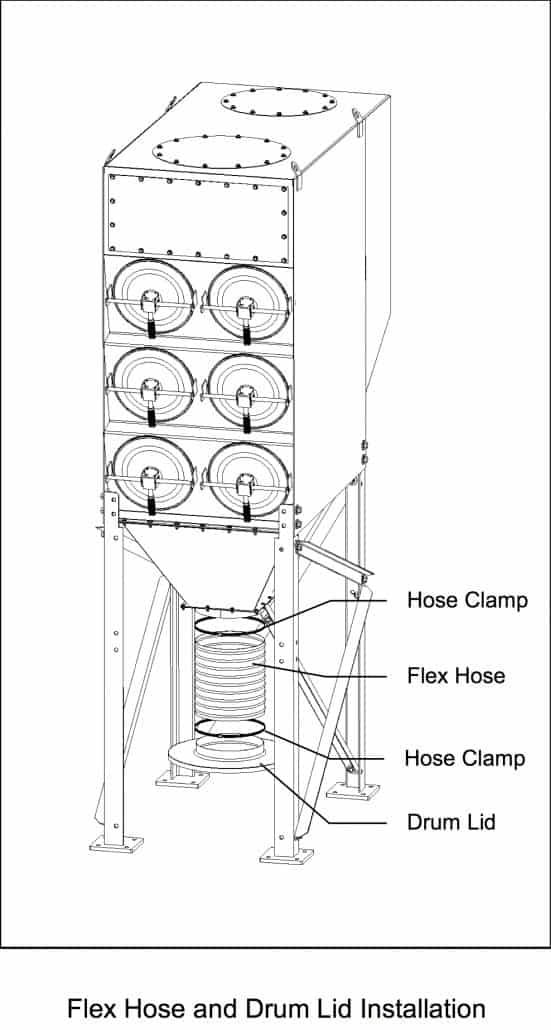

- Dust discharge with sealed drum connection

- Clean on Demand control system with integral differential pressure monitor

- 5 year materials and craftsmanship warranty

- Designed and Built in the U.S.A.

Optional Features

- Abrasion resistant inlet

- Multiple inlets

- Cyclone pre filters

- Air management modules

- Full line of fan and motor combinations for optimized airflow and vacuum

- Variable frequency drive fan motor controls

- Fan silencers and dampers

- HEPA after filter assemblies for meeting OSHA standards when recirculating air into the building

- Alternative filter media options

- (Spark resistant nanofiber, spunbond polyester with wide pleat spacing, spunbond polyester with PTFE membrane, high temperature aramid)

- Rotary airlocks

- Screw conveyors

- Explosion vents

- High speed abort gates

- Backdraft dampers

- Spark arrestors

- Extinguishing systems

- Custom paint and coatings

- High angle hoppers

- Multiple hopper/module designs

- Bag-in/Bag-out option for hazardous dust applicaitons

- Stainless steel construction