Choosing the correct baghouse filter will maximize performance, increase filter life, reduce system downtime and save you money. With so many different types of baghouse filter fabrics and treatments options to choose from, it’s important to know which is the best fit for your specific application. At Baghouse.com we provide our customers with solutions not just the same old filters over and over again. Let Baghouse.com provide you with a free technical analysis and consultation to ensure you are getting the most out of your dust collector filters.

Why Choose Baghouse.com Dust Collector Filters?

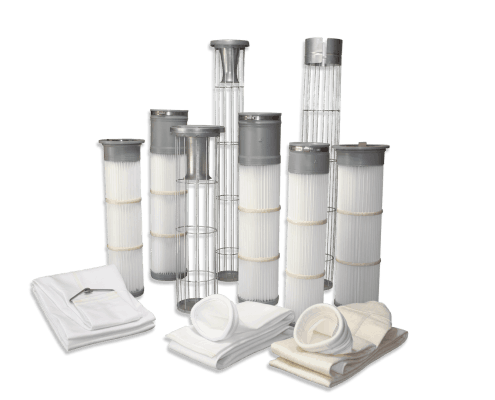

We supply replacement baghouse filters for all makes and models of pulse jet, shaker, cartridge, or reverse-air style dust collectors. Our filters are made to your exact specifications upon order or can be securely stored in one of our warehouses for future use. By buying direct from us, you save by cutting out the middle man. Many baghouse OEMs often charge customers huge markups when buying filters directly through them, just to supply the exact same filter you could buy aftermarket! While many other firms simply sell whatever is convenient for them, Baghouse.com always looks for ways to improve your operation, cut your operating costs, or increase your filter life by offering suggestions for different fabric/finish combinations or conversions to new bag/cage styles or even to pleated filters when speaking with you.

| Baghouse Filters for Every Application and Industry

Baghouse.com provides filters for dust collectors in every industry. Below are some of the most common:

- Asphalt – Durable construction required for abrasive, high temp environments. Hotmix or batch plants, whether natural gas, waste oil, fuel oil, etc. Replacements filters for OEMs like Astec, Gencor, Standard-Havens, etc.

- Cement – Filters for all areas of plant: kilns baghouses, silo bin vents, nuisance dust collection, etc. Our filters exceed all EPA emissions standards (NESHAP, CMAT, MACT for portland cement, PM2.5, etc.). Replacement filters to fit ABB/Flakt, Flexkleen, FLS/Fuller, Mikropul, Norblo, Redecam, Solios and other dust collector OEMs.

- Chemical – Filter fabrics for acidic or alkali compounds, corrosive or abrasive elements, etc. (lime, calc, fertilizer, plastics, etc.) – Special treatments and fabrics available. We can advise on the best combination for performance and cost.

- Food Processing – FDA approved food-grade fabrics construction available for dust collectors used in food production, transportation and packaging such as dust collectors on milling equipment, blenders, mixers, granulators, grain elevators, storage silos and more.

- Foundry and Metal Products – Filters for units used on arc/induction furnaces, casting operations, and precious metal reclamation. Fabrics and coatings for use in high temperature environments with need for high efficiency fume and smoke collection. Filters to fit major OEMs like Amerex, Norblo, Wheelabrator, and others.

- Power Generation and Industrial Boilers – Our filters exceed new EPA emissions regulations for boilers and power generation (Mercury and Air Toxics, Boiler MACT, NESHAPs, etc.). We have much experience working with biomass and coal power production facilities to overcome technical challenges to meet new EPA regulations. Filter fabrics and treatments include PPS, P84, PTFE/Teflon (fabric), fiberglass, and ePTFE membrane.

- Wood, Sand and Minerals – Often requires filters with flame resistant coatings, or constructed from nonflammable materials. We can manufacture filters to fit collectors from MAC, Murphy-Rodgers, Pneumafil, Torit, Farr and others.

Unique Applications

For relatively low to medium temperature operations (Up to 300°F normal operating, 350°F surges) , many collectors perform the best using filters made from polyester, and polypropylene felts. In many applications that have heavy dust loads but require high efficiencies such as cement production, or power generation (coal-fired, etc..), the use of fabric laminated with ePTFE membrane is the best option.

For higher temperature processes, (400°F normal operating temp, 450°F surges or higher), high temperature fabrics such as Conex™/Nomex™ felts (Aramid fabrics) and P84™ polyimide felt can be employed.

Certain applications require dust collector filters with special properties. Filters used in food processing may need to have a food grade rating in order to meet safety regulations. Other processes necessitate the use of antistatic fabrics and coatings such as epitropic felt with antistatic coating. Others need to be acidic or alkali resistant such as homopolymer acrylic felt.

| Selecting the Correct Baghouse Filter is Vital for Obtaining Optimum Performance from your Baghouse

The most important part of any baghouse is the filters themselves. Selecting the wrong type of filter will result in the system performing inefficiently, emitting excess pollutants and damage to other system and plant components. However, the correct filter will maximize performance, increase filter life and reduce system downtime and thus save you money. That is why it is vital to select the correct filters for your baghouse, and see that they are installed correctly.

Still Not Sure What Kind of Filter You Need?

Baghouse.com provides clients with a free technical analysis and consultation to ensure they are getting the most out of their filters. Our Baghouse experts can assist you in selecting the best baghouse filter option for your application. Contact us today for a free Baghouse filter quote, or arrange to have one of our dust collection experts visit your facility and help you determine what areas of your operation you could improve. To learn more about your options please see this article in our resources section: How to Choose the Correct Baghouse Filter or visit our blog for more articles.

| Fabrics | Polypropylene | Acrylic | Polyester | PPS | Aramid | P84††† | Fiberglass† | PTFE Felt |

|---|---|---|---|---|---|---|---|---|

| Max. Continuous Operating Temperature | 170°F (77°C) | 265°F (130°C) | 275°F (135°C) | 375°F (190°C) | 400°F (204°C) | 356–500°F (180–260°C) | 500°F (260°C) | 500°F (260°C) |

| Abrasion | Excellent | Good | Excellent | Good | Excellent | Fair | Fair | Good |

| Energy Absorption | Good | Good | Excellent | Good | Good | Good† | Fair† | Good |

| Filtration Properties | Good | Good | Excellent | Excellent | Excellent | Excellent | Fair | Fair |

| Moist Heat | Excellent | Excellent | Poor | Good | Good | Good | Excellent | Excellent |

| Alkalines | Excellent | Fair | Fair | Excellent | Good | Fair | Fair | Excellent |

| Mineral Acids | Excellent | Good | Fair | Excellent | Fair | Good | Poor†† | Excellent |

| Oxygen (15%+) | Excellent | Excellent | Excellent | Poor | Excellent | Excellent | Excellent | Excellent |

| †Sensitive bag-to-cage ††Fair with chemical- or acid-resistant finishes †††Must oversize bag for shrinkage above 450°F (232°C) |

| Finishes | Purpose | Available For | |

|---|---|---|---|

| Non-Fiberglass | ePTFE Membrane | For capture of fine particulate, improved filtration efficiency, cake release and air flow capacity | Polyester, Aramid, Acrylic, Polypropylene (felt and woven), P84, PPS, Teflon/PTFE |

| Singe | Recommended for improved cake release | Polyester, Polypropylene, Acrylic, Aramid, PPS, P84 (felts) | |

| Glaze/Eggshell | Provides short-term improvements for cake release (may impede air flow) | Polyester, Polypropylene (felts) | |

| Silicone | Aids initial dust cake development and provides limited water repellency | Polyester (felt and woven) | |

| Flame Retardant | Retards combustibility (not flame-proof) | Polyester, Polypropylene (felt and woven) | |

| Acrylic Coatings (Latex Base) | Improved filtration efficiency and cake release (may impede air flow in certain applications) | Polyester and Acrylic felts | |

| PTFE Penetrating Finishes | Improved water and oil repellency; limited cake release | Polyester, Aramid (felt), PPS | |

| Acid Resistant | Helps shield glass yarn from acid attack to extend life | Polyester, Aramid, Acrylic, Polypropylene (felt and woven), P84, PPS, Teflon/PTFE | |

| Oleophobic | Improves resistance to oils and moisture. | Polyester, Aramid, Acrylic, Polypropylene (felt and woven), P84, PPS, Teflon/PTFE | |

| Finishes | Purpose | Applications | |

| Fiberglass | ePTFE Membrane | For capture of fine particulate, improved filtration efficiency, cake release and air flow capacity | Cement/lime kilns, incinerators, coal- red boilers, cupola, ferrosilica/alloy, furnace |

| Silicone, Graphite, ePTFE | Protects glass yarns from abrasion, adds lubricity | Coal-fired boilers, carbon black, incinerators, cement, industrial and boiler applications | |

| Acid Resistant | Helps shield glass yarn from acid attack to extend life | Coal-fired boilers, carbon black, incinerators, cement, industrial and boiler applications | |

| ePTFE (bath) | Provides enhanced fiber-to-fiber resistance to abrasion and limited chemical resistance | Industrial and utility base load boilers under mild pH conditions, cement and lime kilns | |

| Blue Max CRF-70** | Improved acid resistance and reduces fiber-to-fiber abrasion, resistant to alkaline attack, improved fiber encapsulation | Coal-fired boilers (high & low sulfur) peak load utilities, boilers, carbon black, incinerators |

We make replacement filters to fit every dust collection system OEM:

| Aaron | Clark's Sheet Metal | ICA/Ecolair | Saunco |

| Aerodyne | Clemco Mfg. | ICM | Semco/Keystone Intl. |

| Aeropulse | CMI | Intensifilter | Seneca |

| Aget | C-E | Interel/Luhr | Scientific Dust Collectors |

| Air Conveying | Dustex | Kice | Spahr |

| Air Sentry | Dusty Dustless/Griffin Env. | Kleissler | Staclean |

| Airtrol | DCE Volkes | Johnson March | Standard Havens |

| Allen Sherman Hoff | Dynamic Air | Lear Siegler | Standard Metals |

| Amerex | Eastern Control Systems | Lamson | Stansteel |

| American Air Filter | Emtrol | Mac | Steelcraft |

| American Std | Environmental Elements | McCarter | Tarmac |

| Argo Blower | Esstee Mfg. Co. | Mikropul | Torit/Donaldson |

| Astec Industries | Evo | Moldau | Tech-Air |

| BACT Engineering | ExCel Air | Murphy-Rodgers | Ultra Industries |

| Bahnson Hawley-Norblo-Envirotech | Farr | Pangbom/Carborundum | US Air |

| Balox | Fabrics Filters N.W. | Norblo | United Air Specialist |

| Barber-Green | Filter Corp. | Parsons | United Conveyor |

| Baumco | Flakt | Peabody Process System | WW Sly |

| Belco | Flex-Kleen | Percy Todd Mfg. | Western Pneumatics |

| Bituma Construction | Fulter | Perlite | Westinghouse |

| BMG | GMD Engineered Systems | Pneumafil | Wheelabrator-Frye |

| Brandt Engineering | GenTec | Premier Pneumatics | Wiedenmann |

| Buell/Norblo | General Resource | Procedair Ind. | Young Ind. |

| Buffalo Forge | George Rolfes | Rayjet/CEA | Zero |

| Buhler-Miag | Green Steel | Rees | Zurn Air Industires |

| Carter-Day | Guzzler | Research-Cottrel | |

| Cedar Rapids | Hoffman | Ruemelin Mfg. |

GET YOUR FREE FILTER QUOTE TODAY

Let us give you a free quote on your next set of replacement dust collector filters today! Call us at (702) 848-3990 or fill our the filter quote form and receive a price the same day!