Baghouse.com offers a full line of dust collector controllers, timers, and sequencers for use on any baghouse dust collector. Our controllers work with any model pulse jet dust collector regardless of the OEM. By replacing your current dust collector timer board with an all-in-one baghouse control board its possible to have both clean-on-demand (clean-on-pulse) and continuous cleaning applications, eliminating the need for external devices such as pressure switches, relays, and other timers.

| Cleaning your dust collector filters based on differential pressure is key to increasing efficiency, extending filter life, and lower emissions

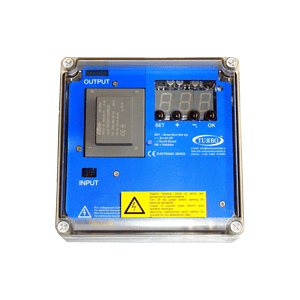

Our dust collector control boards work as both traditional timer boards or as clean-on-demand controllers. Additionally, boards come with integrated pressure sensors that can be used to trigger cleaning cycles based on differential pressure for improved cleaning efficiency, longer filter life, and reduced emissions. Even with so many additional features, our controls are comparable in price to a standard Photohelic and timer board installation.

Standard Features:

- Manual selection of output number / solenoid valve

- Adjustable activation time per each output from 0.05 to 5 sec. (combine with adjustments to cleaning PSI to improve bag cleaning efficiency)

- Adjustable interval time between two activations from 1 to 999 sec. (delay between pulses; allows air pressure to build in air header before firing)

- Short circuit output protection

- Manual activation of each single output

- Digital differential pressure control

- Differential pressure reading by internal transducer (max 10kPa)

- Maximum dP alarm with alarmed contact open and automatic reset

- Zero dP reading adjustment

- 10kPa dP reading full range

- Additional post-cleaning cycle after fan stop

- Cleaning cycle ON/OFF by volt free external contact

- Max 25W load power per each output

- Input and output selection by JP1, JP2 and JP3 jumpers on the board

- IP65 rated plastic enclosure

- 2 year warranty

Add-on Options:

- 4-20mA relay for remote monitoring/control of the dP settings from a PLC

- G-2 Models-Pulse two valves per contact, doubling capacity of controller

- Metal enclosure (dust proof, explosion proof, water proof, etc.)

- Download Turbo Control Board Manual

Baghouse Controllers – Key to Increasing Dust Collection Efficiency

Often times the key to baghouse efficiency is operating the pulse jet cleaning system correctly. Both over-cleaning and under-cleaning your bags will cause problems. A simple upgrade to a new clean-on-demand dust collector controller from an older, less-efficient baghouse timer board usually results in more cost savings than larger investments such as new bags or system modification.

With a clean-on-demand (pulse-on-demand) control system, your dust collector cleaning system will only activate when its needed, no more, no less. Simply set the upper and lower (low/high) differential pressure points, (normally 3.5” and 5.5” w.g.), and the controller will trigger the cleaning cycle only when the DP rises above the high setting, and will continue to clean until it drops below the low setting. This results in the bags being cleaned less frequently, saving on costly compressed air and reducing wear on the filters themselves. Additionally, it lowers overall emissions and helps regulate the system performance by keeping it running in a consistent differential pressure range.

For these reasons and more, our advanced system audits frequently recommend switching to new baghouse pulse controller as an easy way to improve efficiency, reduce operating costs, and increase system capacity/performance.