In nearly every industrial facility, a dust collection system is a vital component for efficient operation. Their operation, reliability and efficiency directly impact profits at your facility (e.g. System downtime, high energy costs, lost production, environmental/workplace safety fines, etc.). Therefore, the choice of your industrial dust collection system is by no means one to be taken lightly. Baghouse.com can provide the exact industrial dust collector you require. Unlike many of our competitors who offer large product lines of “cookie cutter” designs, Baghouse.com custom manufactures each collector to meet the specific needs of the customer without charging the inflated rates commonly associated with custom design.

Why Choose a Baghouse.com Dust Collector

Our dust collectors are known for their high quality construction and reliability as well as being easy to maintain. With over 40 years of experience manufacturing, servicing and optimizing industrial dust collectors, we have gained unique insight into what works and what does not. This enables us to design and build our collectors in such a way as to avoid many of these common issues from other manufacturers. (e.g. placing the pulse valves at hand level on top of the unit platform rather than on its side where access is difficult.)

| Baghouse Builds Them Better

This is just one example of the many standard value-added features that are included in all Baghouse.com models. Other features include expanded inlet diffusers, expanded quiescent free-board zone (i.e. clear space under filters) and clean on demand (clean on pressure) controllers.

Larger inlet diffusers prevent hopper turbulence, dust re-entrainment and facilitate material drop-out. Additionally, our units come with an expanded quiescent free-board zone between the inlet and the bottom of the filter bags that reduces unnecessary dust load, filter abrasion and interstitial velocity that further enhancing material drop-out all before the air stream even reaches the filters.

Finally, Baghouse.com industrial dust collectors come equipped with “Clean-on-demand” controller systems that allows for bag cleaning based on differential pressure. This results in direct savings from lower compressed air usage, extended filter life, and lower emissions over the life of the filters/unit.

Designed and Built to Meet Your Requirements

All too often we see users that are sold a unit that is the wrong kind or is undersized by disreputable sales reps. They do whatever it takes to get the sale, even if it means selling the wrong kind of unit or undersizing it in order to underbid everyone else. Sadly, in the long run these tactics end up costing the end user far more than the minimal discount they received. (See article: How to Avoid Undersizing a Baghouse Dust Collection System)

At Baghouse.com, we pride ourselves on “providing our customers with solutions not just products”. This means that we will use our experience to offer you what we know will work best for you, both in the short term and the long term. We will never quote you an undersized system just to undercut other vendors, nor will we propose old, outdated dust collection technology like many other OEMs and sale rep organizations.

| Our Dust Collector Product Lines

Bin Vents

Beware Of So-Called "Experts" Offering Undersized Units Or The Wrong Style Collector

At times so-called dust collector “experts” can try to convince you to purchase the wrong style collector for your application or a one that is too small! Often this happens when they only have a limited product line with one style collector to offer since they do not design and manufacture their own units. Or they want to offer the lowest priced proposal for your project, regardless of whether or not it will perform adequately in the long. In contrast, Baghouse.com will always recommend an properly sized dust collector that will exceed your performance needs every time! We design and manufacture a full line of baghouses, cartridge collectors, cyclone collectors and bin vents so we can provide the right unit for your application.

TOP ACCESS UNITS

Top Access Pulse Jet Baghouse (Baghouse.com TA Series)

- 100 CFM – 50,000 CFM (9) – (592) filters

- Square housing

- Top hatch access

- Easy access pulse valves mounted on top railing

- Filter lengths 8’, 10’, 12’

- One or two-piece cage designs

- Optional pleated filter elements

- Extended hopper

- Caged Ladders

- Additional Platforms and support structures

- Rectangular, or round housing (high pressure)

- Compartmentalized Systems (>10,000 CFM)

- High or otherwise custom inlets

- Explosion/Fire Protection

- Stainless steel construction

- Bin Vent Construction (i.e. no hopper)

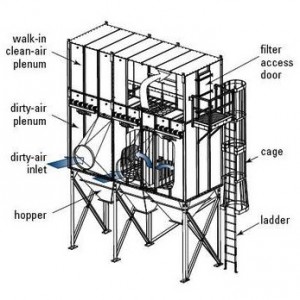

Top Access Pulse Jet Baghouse – Walk-In Plenum (Baghouse.com TAWP Series)

- 1,000 CFM – 100,000+ CFM (36) – (1,248) filters

- Square or Rectangular housing

- Covered Top Access (i.e. Walk In Plenum)

- Easy access pulse valves mounted near entrance to clean air plenum

- Filter lengths 8’, 10’, 12’

- One or two-piece cage designs

- Optional pleated filter elements

Additional Options:

- Extended hopper

- Caged Ladders

- Additional Platforms and support structures

- Rectangular, or round housing (high pressure)

- Compartmentalized Systems (>10,000 CFM)

- High or otherwise custom inlets

- Explosion/Fire Protection

- Stainless steel construction

- Bin Vent Construction (i.e. no hopper)

BOTTOM ACCESS UNITS

Bottom Access Pulse Jet Baghouse (Baghouse.com BA Series)

- 100 CFM – 10,000 CFM (9) – (100) filters

- Square housing

- Side Hatch Access

- Filter lengths 8’, 10’, 12’

- One-piece cage

- Optional pleated filter elements

Additional Options:

- Extended hopper

- Caged Ladders

- Additional Platforms and support structures

- High or otherwise custom inlets

- Explosion/Fire Protection

- Stainless steel construction

- Bin Vent Construction (i.e. no hopper)

Bottom Pulse Jet Baghouse – Round (High Pressure) (Baghouse.com BAR Series)

- 100 CFM – 10,000+ CFM (7) – (164) filters

- Round housing with option for high pressure construction

- Side Hatch Access

- Filter lengths 8’, 10’, 12’

- One piece cage

- Optional pleated filter elements

- Bin Vent Construction (i.e. no hopper)

Additional Options:

- Extended hopper

- Caged Ladders

- Additional Platforms and support structures

- Rectangular, or round housing (high pressure)

- Compartmentalized Systems (>10,000 CFM)

- High or otherwise custom inlets

- Explosion/Fire Protection

- Stainless steel construction

When possible, we recommend our customer choose one PF-Series units designed to use pleated filter elements. Pleated filters have a much great filter cloth area compared to traditional bags, which means pleated units can be smaller but handle more airflow. Their one-piece construction means pleated filters install much easier, making filter changeouts faster and simpler. They also last on average twice as long as bags and use less compressed air over time. Learn more about the benefits of pleated filter elements here or see a sample cost benefit analysis of switching from bags to pleated filters.

Cartridge Collectors

Front Access Pulse Jet Cartridge Collectors

- 500 CFM – 100,000+ CFM (4) – (128) cartridge filters

- Nano-Fiber high efficiency MERV 15 filter media

- Front loading cartridges with quick release handles

- Multiple inlet options

- Downflow design to prevent dust reentrainment

- Easy access pulse valves with venturi for peak cleaning efficiency

- Integrated clean on demand controller and differential pressure monitor

- 5 year material and workmanship warranty

Additional Options:

- Abrasion resistant inlet

- Multiple fan and motor configurations

- Multiple or single hopper configuration

- Cyclones, knockout chambers and air management modules for heavy dust loading applications

- Rotary and double dump airlocks

- Screw conveyors

- Explosion vents, abort gates and sprinkler connections for combustible dust applications

- HEPA after filters for recirculating to plant or HazMat applications

- Triboelectric bag leak detectors for emissions monitoring

- Stainless Steel construction

LEARN MORE ABOUT BAGHOUSE.COM INDUSTRIAL DUST COLLECTION SYSTEMS

To learn more about the advantages of Baghouse.com brand equipment, and how we help you to improve your industrial dust collection system, please contact us today!

Have all your information? Use this detailed quote form