Clogged machinery, exposure to hazardous chemicals, and disruptions in plant processes, are just a few of the problems that come from using your dust collector hopper for dust storage.

February 25, 2012 | Baghouse.com News – One of the most common baghouse operation practices that we find when we send a dust collector technical advisor out to various facilities is that many plants unwisely use the hopper on their dust collector for storage of the collected dust. Sometimes this is done unwittingly, as maintenance staff simply overlook emptying the hopper on a regular basis. Other times, this is more or less included (unwisely), into the design by neglecting to install a discharge system, such as a screw conveyor, or slide gate mechanism.

“You dust collector is NOT designed to store collected material for extended periods of time.”

However, whether this course of action is planned or not, using your dust collector hopper for storage of any collected material for an extended period of time can cause a myriad of problems. Among the various problems that can arise are damage to dust collector bags, increased emissions, increased pressure drop (i.e. increased system airflow resistance), and clogging and damage to dust discharge systems (conveyor systems, slide gates, etc.).

In addition, in some instances involving compounds that may be considered hazardous, storing collected materials in the hopper can lead to extensive fines and prosecution from governmental regulators such as OSHA or the EPA.

A Foundry Runs Afoul of OSHA and The EPA, Lands President and Company in Criminal Court

Recently, a Franklin, New Hampshire metal parts manufacturer and its president pleaded guilty to charges stemming from what OSHA found to be unlawful storage of hazardous compounds. The hazardous or toxic compounds in question were byproducts of the plants manufacturing process, that contained high levels of lead and cadmium. The plant and its president according to court records, knowingly stored the waste with the hazardous levels of lead and cadmium in unapproved containers throughout the plant for longer than the 90 days allowed by law without notifying OSHA and the EPA.

During an inspection of the plant by OSHA in 2009, the plant was found to be in violation of the Resource Conservation and Recovery Act (RCRA), which requires a permit to store hazardous waste on site for longer than 90 days. OSHA notified the EPA of their findings, and then a few months later, the EPA executed a search warrant on the plant found drums of hazardous waste being stored at the plant.

In the end, a federal grand jury indicted Wiehl and Franklin Non-Ferrous Foundry for unlawfully accumulating and storing lead and cadmium hazardous waste at the foundry site since July 2005. Wiehl faces a possible maximum sentence of two years in prison and a maximum fine of $250,000. Under the terms of a plea agreement filed with the court, the United States Attorney’s Office has agreed to recommend that he serve two years of probation, six months of house arrest, and that he publish a public apology. Franklin Non-Ferrous Foundry, Inc is facing a possible maximum fine of $500,000.

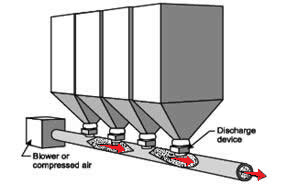

Ensure your dust collection system regularly discharges into a dust conveyor system, such as a screw conveyor.

What’s The Lesson? Store Collected Dust Properly!

While the situation with manufacturer discussed above did not involve storing material in the dust collector, it does demonstrate that the EPA, and OSHA (and other safety organizations) do not take kindly to the storing of chemicals and compounds in inappropriate ways. You dust collector is NOT designed to store collected material for extended periods of time.

As already mentioned, using your hopper to store dust will lead to a score of problems that adversely affect not only the efficiency of your dust collection system, but your entire plant. These problems drastically increase if the collected dusts contain hazardous materials (lead, mercury, etc.), are an explosion hazard (food products, metal powders, fertilizer, etc.) or are corrosive to machinery. In these instances it is imperative that proper dust transportation, storage and disposal methods are implemented. These include the use of continuous hopper cleaning (such as timed or sense actuated slide gates, pneumatic locks, etc.). It is also vital to regularly check these systems, specially those components most prone to wear and failure such as slide gates, seals, etc.

| Dominick DalSanto is an Author & Environmental Technologies Expert, specializing in Dust Collection Systems. With nearly a decade of hands-on working experience in the industry, Dominick’s knowledge of the industry goes beyond a mere classroom education. He is currently serving as Online Marketing Director & Content Manager at Baghouse.com. His articles have been published not only on Baghouse.com , but also on other industry related blogs and sites. In his spare time, Dominick writes about travel and life abroad for various travel sites and blogs.