The EPA has issued proposed revisions to emissions standards for boilers and solid waste incinerators. These new rules once finalized will lead to increased demand for dust collection systems throughout industry.

December 23, 2011 Baghouse.com News – The Environmental Protection Agency proposed several revisions to its emissions standards for boilers and solid waste incinerators. The EPA rules set emissions limits for several different hazardous air pollutants, including mercury, particulate matter 2.5 (PM2.5) dioxins, cadmium, nitrogen dioxide and lead among others.

The rules, The Air Toxics Standards For Industrial Commercial and Institutional Boilers (Major and Source Facilities) and New Source Performance Standards (NSPS) and Emissions Guidelines (EG) for Commercial and Industrial Solid Waste Incinerators (CISWI), were originally proposed back in March 2011. The reason for the revisions according to the EPA was to address concerns raised by the public, and owners/operators during the public comment period. According to the EPA the proposed changes will still result in significant reductions in most pollutants, and even larger reductions in some, while limiting the financial burden from implementation as much as possible.

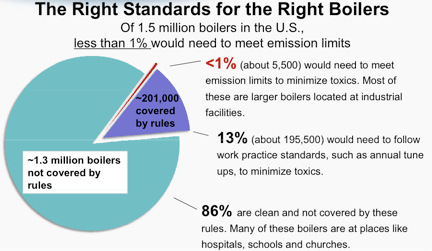

The revised rules will require only a small percentage of the total boilers in the U.S. to install pollution control equipment such as dust collection systems. The vast majority (86%) of boilers will not be covered by the rules at all, others (13%) will only be required to perform regular maintenance, and tune-ups to stay in compliance (also termed “workplace practices”). The remaining less than 1% of boilers are responsible for the vast majority of air pollution in this sector. They are mainly found in chemical processing, oil refineries, and other heavy industries. By retooling the rules to focus only on the largest emitters, the EPA hopes to improve flexibility in reaching compliance for smaller institutions.

The revised rules will require only a small percentage of the total boilers in the U.S. to install pollution control equipment such as dust collection systems. The vast majority (86%) of boilers will not be covered by the rules at all, others (13%) will only be required to perform regular maintenance, and tune-ups to stay in compliance (also termed “workplace practices”). The remaining less than 1% of boilers are responsible for the vast majority of air pollution in this sector. They are mainly found in chemical processing, oil refineries, and other heavy industries. By retooling the rules to focus only on the largest emitters, the EPA hopes to improve flexibility in reaching compliance for smaller institutions.

The new regulations will result in over 8,100 premature deaths, 5,100 heart attacks, and 52,000 asthma attacks being avoided each year starting by 2015. The EPA estimates that for every $1 spent complying with these new regulations, the public will see $12 to $30 in health benefits. These results will be realized by reducing emission levels of compounds like mercury and lead, which are proven to cause developmental problems in young children and nervous system damage in adults and children, as well as by reducing particulate matter i.e. dust pollution, which is a severe asthma aggravator.

Existing major source boilers will have three years to come into compliance with the new regulations, with an additional year if needed technologies cannot be installed by then. CISWI units will have five years to comply.

The estimated annualized cost of the rule, as amended based on the reconsideration proposal, would be $1.49 billion, compared with $1.40 billion for the final rule. The estimated annualized cost would increase by about $90 million due to the addition of approximately 300 affected units to the revised inventory of units. This is the case even with a decrease in the stringency of some emission limits and less stringent PM control requirements for biomass units in the proposal.

Different Regulations For “Area Source” and “Major Source” Boilers

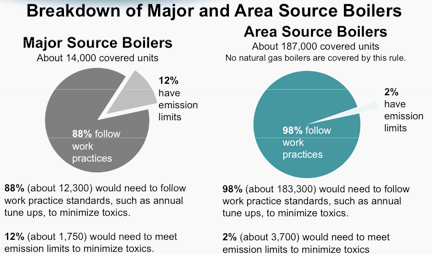

Boilers which only produce small amounts of air pollution are classified as “area source” boilers, and are mainly found in places like churches, hospitals, and commercial buildings. The majority of these burn natural gas (1.3 million), as such they are not covered by this rule. The remaining 187,000 area source burners that do not use natural gas would be covered by the new rules, of these only approximately 2% would have emissions limits, the other 98% would only need to follow workplace practices to stay in compliance.

Boilers which only produce small amounts of air pollution are classified as “area source” boilers, and are mainly found in places like churches, hospitals, and commercial buildings. The majority of these burn natural gas (1.3 million), as such they are not covered by this rule. The remaining 187,000 area source burners that do not use natural gas would be covered by the new rules, of these only approximately 2% would have emissions limits, the other 98% would only need to follow workplace practices to stay in compliance.

Boilers that create large amounts of air pollution are classified as “major source” boilers. Of these approximately 14,00 boilers, most of which are found at heavy industrial sites such as refineries, and chemical processing plants, an estimated 88% (about 12,300) would only need to follow best work place practices, while the remaining 12% (about 1,750) will be required to reduce emissions, as well as increased monitoring, and record keeping.

Revisions Based On Public Comments

After allowing several months for public and industry comments regarding the original proposal, the EPA has included several of these suggestions into its revised proposal. Many of these are in response to claims that the original proposal was to restrictive in requiring the same standards across many different types of boilers in many different locations, applications, and that use different fuel sources. Among the proposed changes to make compliance easier, and fairer are the following:

Major Source Boilers:

- Subcategories for different types of light and heavy liquid fuels

- To reflect the real world differences in operating standards and requirements between the fuels

- Different limits for PM 2.5 for different fuels

- Different limits for boilers using biomass, coal, etc.

- Revised limits for carbon monoxide

- Subsequent studies have been provided that show that CO emissions vary greatly between boilers, and one universal limit is not practical

- Allow for a alternative total selective metals emissions limit for select air toxics

- To ease compliance costs, and improve flexibility

- Remove dioxin limits and replace with work place practice requirements

- Based on subsequent analysis showing dioxin levels in boilers are often well below accurately detectible levels

- Increased flexibility in compliance monitoring requirements

- Allow for monitoring from stack or continuous monitoring, and remove continuous monitoring requirement for biomass boilers

- Remove emissions limits for units outside continental United States

- To deal with unique operating circumstances and requirements for these units

- Allow “clean gas” boilers to continue to be exempt from new standards

- To improve flexibility and ease of compliance

Area Source Boilers:

- Alter Initial tuneup schedule

- Change compliance timeframe to two years, instead of one, create new categories of boilers and increase overall flexibility in compliance requirements

- Alter tuneup schedule/requirements for seasonal units

- Change from every other year to every five years for these infrequently employed units

Revisions To Commercial and Industrial Solid Waste Incinerators (CISWI) Standards

A CISWI unit is any device that is used to burn solid waste at a commercial or industrial facility. Examples of CISWI units include incinirators used to burn solid waste (i.e. garbage), energy recovery units designed to recover heat that combust solid waste; and kilns designed to manufacture products and also combust solid waste.

The revised CISWI standards provide for stricter emissions limits on nine major air pollutants regulated by the EPA (mercury, PM 2.5, lead, etc.). In addition, the new standards provide for new definitions of what exactly qualifies as solid waste, hazardous waste, etc. Many of the revisions for the new standards requested increased clarification in these areas. The subsequently revised standards have increased clarification on what materials are categorized as, allow for certain “non-hazardous secondary materials” to not be classified as solid waste when used as a fuel (e.g. certain wood products that are used as part of biomass fuel sources) and allow for plant operators to request the EPA to clarify, and reclassify certain materials based on site specific considerations.

The EPA estimates that, for some units, it would be more cost-effective to use an alternative disposal option. If those units use alternative disposal options, and the remainder use add-on controls, the total nationwide cost would be approximately $270 million. If all 95 CISWI units currently in operation use add-on controls, the total nationwide cost for complying with the rule, as amended, would be approximately $284 million per year.

What This Means For The Future

The EPA believes these newly revised standards will provide both added health benefits, and environmental protection while still not creating an unbearable burden for operators. “With this action, EPA is applying the right standards to the right boilers,” said Gina McCarthy, assistant administrator for EPA’s Office of Air and Radiation. “Gathering the latest and best real-world information is leading to practical, affordable air pollution safeguards that will provide the vital and overdue health protection that Americans deserve.”

WIth these new standards set to take effect in the near future, dust collection systems, baghouses, baghouse filters, etc. will be in high demand as many existing plants require extensive upgrades in order to reach compliance. In addition to these standards, the EPA’s newly issued mercury rule will also in many technologies (such as activated carbon injection) require upgrades to existing dust collection systems, or at minimum investments in more efficient baghouse filters or system tuneups.

About the Author

| Dominick DalSanto is an Author & Environmental Technologies Expert, specializing in Dust Collection Systems. With nearly a decade of hands-on working experience in the industry, Dominick’s knowledge of the industry goes beyond a mere classroom education. He is currently serving as Online Marketing Director & Content Manager at Baghouse.com. His articles have been published not only on Baghouse.com , but also on other industry related blogs and sites. In his spare time, Dominick writes about travel and life abroad for various travel sites and blogs.