Dust collection systems are often overlooked when it comes to plant improvements due to the often high capital costs involved. We here at Baghouse.com have prepared this small list of improvements that can be made to your dust collection system with minimal investment.

October 26th 2011 | Baghouse.com – Corporate executives are looking for any conceivable way to lower operating costs in our struggling economy, plant operators are being pushed by the corporate brass to find someway of doing more with less, and maintenance managers are trying to make sure all of these cutbacks do not compromise process operation. One area that many industrial plants can easily increase efficiency, and therefore lower operating costs is to look to their pulse jet baghouse dust collection systems.

Here are three small tweaks for your pulse jet dust collection system to increase operating efficiency without a major overhaul or great expense.

1. Ensure Filter Bags Are Installed Correctly

2. Install a Clean-On-Demand System

3. Integrate All System Controls (Clean-on-Demand, timer boards, manometers, etc.)

1. Correctly Install Filter Bags

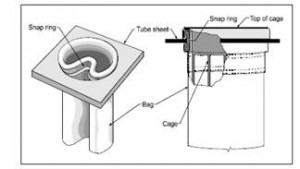

Filter Bags are the heart and soul of a baghouse. If they are not installed correctly the entire system will suffer, efficiency will go down, filters will fail prematurely, system downtime will ensue and affect the entire process. Check that filters with flanges and cuff are folded over and smooth and not wrinkled around the cage to prevent leakage, and premature failure due to bag abrasion. Bottom-loading filters should be installed with seams 180° from the cage collar gap.

An example of how a snapband filter bag should be installed to maximize your dust collection system efficiency.

Additionally, there are several specific issues to watch out for depending on the exact design of filter bags being used. For snapband construction, check that the seams are set properly in the tubesheet. This can be done running your fingers along the edge of each bag during installation/maintenance checking that each one is smooth, with no wrinkles, gaps, or binds in the snapband. For designs with gaskets or rubber o-rings make sure these are not pinched by the clamps in a way that will allow leaks, or cause accelerated wear.

Additionally, with all bag types, all seams should be at a 45° angle from the aisle to minimize fraying due to increased can velocity, all clamps should be set 90° from the seams, and all filters need to be set properly in the cage groves.*

*Additional Tip: Have everything as uniform (clamps, seams, etc. all set in the same direction) as possible to make it easier to diagnose and remedy problems.

2. Clean-On-Demand System

Manually having a technician initiate the cleaning cycle for your dust collection systems can consume a large amount of time, and lead to less than desirable results such as over/under cleaning, operating at higher differential pressure (raising system resistance, and fan load), and lower collection efficiency. Simplify the process and remove the need to be a industrial filtration expert out of the equation by installing a clean-on-demand system.

Using a clean-on-demand timer board for your baghouse will simplify the cleaning process, and result in more effective cleaning of your dust collection system.

These systems are comprised of a differential pressure gauge, and a control board. The DP gauge monitors the difference in pressure between the clean-air and dirty-air sections of the baghouse (thus giving you the pressure drop over the filters at any given time). DP gauge is connected to the control board, which has a high and low pressure setting which serve as the start and stop markers for the system. When the DP in the baghouse rises past your high setting (indicating the bags need to be cleaned), the controller starts the pulse-jet cleaning cycle, once the pressure reaches the preset low, the pulse-jet system is disengaged.

For a relatively small capital investment clean-on-demand systems can dramatically improve your system efficiency by ensuring the minimum amount of cleaning cycles necessary are initiated, which in turn leads to lower compressed air usage, lower operating differential pressures, and less filter wear. These benefits will lower system operating maintenance costs, while seeing improvement in collection efficiency, and extended filter bag life.

3. Integrate Dust Collection System Controls

Maintaining the correct amount of dustcake on your filters is essential to achieve the maximum collection potential of your filter bags. In fact it is the dustcake itself that does the filtering in a baghouse, not the filter bags! * When the pulse-jet cleaning system engages, it removes the excess dust from the filter surface. Essentially what this does is rearrange the dustcake on the filters, removing a portion of it, and leaving behind the minimum amount needed to reform the dustcake for optimum efficiency. When cleaning cycles are carried out, if each row is pulsed one after another in sequential order, high internal air velocities between the filters (can velocity) can cause the recently dislodged dust to be redeposited on the recently cleaned bags in the previous rows. Since the dust is carried at higher than normal velocities, it can penetrate the fabric (instead of settling on top and forming part of the dustcake) and embed itself therein. This will eventually lead to filter blinding, and a reduction of filter service life.

Installing a sequential controller can help you avoid this problem. This device controls the order in which the bags are cleaned, staggering the cleaning pulse pattern between non-adjacent rows. For example, in a baghouse with 10 rows of bags, you can set the cleaning pattern to first clean rows 1,4,7,10 then 2,5,8, and finally, 3,6,9. You can also set the controller to only fire when the pressure in the compressed air header is at full, providing a consistent pulse force that will properly clean the bags every time. Additionally, to further promote longer filter life, see that each pulse duration is set as short as possible, generally around 0.1 sec.

If you do not currently have a DP clean-on-demand system, an alternative is to use a timer control to regulate system cleaning. When using a timer board setup, it is vital to set the intervals to match your system parameters, ensuring that the filters are neither over, or under cleaned. Maintaining a sufficient level of dustcake is vital to achieving a high system efficiency.

Finally, it is possible to integrate all of these different systems into one unified control panel for operator convenience. You can have all of your controllers relayed to a central LED controller, which then is connected to an external PLC controller or computer for remote monitoring, and recording of all system activity. From here it is then possible to configure all control parameters e.g. timer settings, clean-on-demand DP points, pulse-jet firing order, etc. Additionally, having all operating data in one convenient location will allow for quickly pinpointing problems before they become major issues.

*This does not apply to filter bags with membrane such as ePTFE. In that case, the membrane itself acts as a sort of permeant filter cake while surface dust provides no additional filtering.

Save Money By Increasing Dust Collection System Efficiency

These three tips are just a few of the many ways to increase the operating efficiency of your baghouse dust collection systems with only limited investment of time, material, and capital. Without a doubt, these improvements will pay for themselves many times over throughout the life of the system. At a time when new environmental regulations are requiring pollution control equipment to function at higher and higher efficiencies, not only will turing your attention to improving your dust collection systems lower your operating expenses, but it will also ensure that facilities stay in compliance and avoid costly fines and forced closures.

About the Author

| Dominick DalSanto is an Author & Environmental Technologies Expert, specializing in Dust Collection Systems. With nearly a decade of hands-on working experience in the industry, Dominick’s knowledge of the industry goes beyond a mere classroom education. He is currently serving as Online Marketing Director & Content Manager at Baghouse.com. His articles have been published not only on Baghouse.com , but also on other industry related blogs and sites. In his spare time, Dominick writes about travel and life abroad for various travel sites and blogs.