What is a Cyclone Dust Collector?

A cyclone dust collector (also referred to as a cyclone separator or simply a cyclone) is a device that is used to remove particulate matter from air or gas streams. It works on the principle of centrifugal force, which is generated by a rapidly rotating cylindrical chamber.

Unlike a standard dust collector or baghouse that uses filters to collect dust from the air, allowing clean air to pass through, a cyclone dust collector uses centrifugal force and the momentum of the dust-laden air to pull out heavier dust from the air stream. They are particularly effective for removing larger or non-uniform particles (strips and of wood, etc.) that might clog a cartridge or baghouse collector.

How Does a Cyclone Dust Collector Work?

Here’s how a cyclone dust collector works:

Here’s how a cyclone dust collector works:

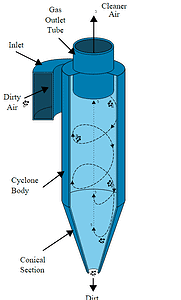

- Dust-laden air or gas enters the cyclone dust collector through an inlet and is directed into a cylindrical chamber.

- The chamber is designed to cause the incoming air or gas to spin around its axis. This creates a centrifugal force, causing the heavier particles to move towards the outer walls of the chamber and eventually drop out and settle at the bottom of the collector.

- The clean air or gas then exits the collector through an outlet located at the top of the chamber.

- The collected particles are collected in a hopper at the bottom of the collector, where they are typically discharged into a bin or other dust discharge method.

When is a Cyclone Separator Needed?

Cyclone dust collectors and baghouse dust collectors are both effective at capturing and removing dust particles from industrial processes, but they are best suited for different applications.

Cyclone dust collectors are typically used for applications that generate large volumes of coarse and heavy dust particles, such as sawdust, wood chips, metal shavings, or granular materials. Cyclones are effective at removing these large particles due to their use of centrifugal force, which causes the particles to be separated from the air stream and collected in a hopper or bin. Cyclones are also relatively simple to operate and maintain, with low maintenance requirements and operating costs.

Baghouse dust collectors, on the other hand, are best suited for applications that generate large volumes of fine and light dust particles, such as welding fumes, chemical dusts, or pharmaceutical powders. Baghouses use a series of fabric filter bags or cartridges to capture the dust particles as they pass through the system. Baghouses are effective at capturing these fine particles due to their high filtration efficiency, which can exceed 99%.

In general, cyclone dust collectors are preferred over baghouse dust collectors for applications where the dust particles are relatively large and heavy, and where the process generates high volumes of material. Baghouse dust collectors are preferred for applications where the dust particles are fine and light, and where high filtration efficiency is required.

Often, a cyclone separator is installed in front (upstream) of a baghouse or other dust collector. The cyclone to remove the heaviest dust particles and the dust collector catches the finer dust. This has the benefit of lowering the dust load on the collector and removing large, sticky, or high-temperature particles before the dust-laden air reaches the collector, improving efficiency and filter life and avoiding the clogging of filters with large dust particles.

Cyclone dust collector upstream of a baghouse dust collector.

However, it is important to consider the static pressure loss of adding a cyclone separator into the air stream as it will increase the required load on the system fan.

It is important to consider the specific requirements of each application when selecting a dust collector to ensure that the system will provide effective dust collection while minimizing operating and maintenance costs.

Are There Different Types of Cyclone Collectors?

Yes, there are different types of cyclone dust collectors, each designed to suit specific applications and operating conditions. Here are a few variations of cyclone dust collectors:

- Single-cyclone dust collectors: This is the most basic and common type of cyclone dust collector. It consists of a single cyclonic chamber where the dust-laden air enters and undergoes centrifugal separation. The heavier particles settle at the bottom of the collector, while the cleaned air is discharged.

- Multiple-cyclone dust collectors: In this configuration, several cyclone chambers are arranged in parallel or series to achieve higher collection efficiencies. Multiple cyclones increase the surface area available for particle separation, improving the overall dust collection efficiency.

- High-efficiency cyclones: These cyclone dust collectors are designed with enhanced geometries and optimized airflow patterns to achieve higher separation efficiencies. They often incorporate modifications such as tapered inlets, vortex finders, and secondary air injection to enhance particle separation and reduce pressure drops.

- Reverse-flow cyclones: Reverse-flow cyclones, also known as reverse-flow dust collectors, operate in a reverse flow direction compared to traditional cyclones. The clean air is directed upward through the cyclone chamber, while the dust particles are collected in a downward flow. Reverse-flow cyclones are particularly useful in applications where the collected material is sticky or prone to re-entrainment.

- High-temperature cyclones: These cyclone dust collectors are specifically designed to handle high-temperature applications, such as those found in industrial processes involving hot gases or exhaust streams. High-temperature cyclones are constructed with materials that can withstand elevated temperatures and are equipped with proper insulation and cooling mechanisms.

Interested in Purchasing a Cyclone Dust Collector?

Contact Us to Speak to One of Our Baghouse Experts.

For more baghouse related training and information, be sure to check out our Baghouse Online Training page.