Background

A prominent aerospace manufacturing client approached Baghouse.com seeking assistance in aligning with Dust Hazard Analysis (DHA) recommendations, which had identified non-compliance with NFPA guidelines for combustible dust hazards.

Scope of Work

Dust Hazard Analysis (DHA) Compliance

- Baghouse.com initiated the project by conducting a thorough assessment of the existing dust collectors and equipment in relation to NFPA guidelines for combustible dust hazards.

- The DHA report highlighted critical gaps that needed urgent attention to ensure compliance and mitigate the risk of combustible dust incidents.

System Consolidation and Upgrade

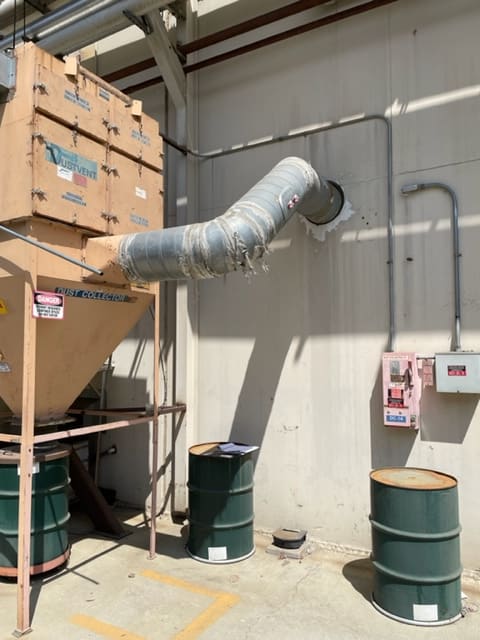

In response to the DHA findings, Baghouse.com proposed consolidating pickups from several older baghouses into a single, more efficient unit.

The baghouse underwent a comprehensive refurbishment, including the installation of new cartridge filters, pulse valves, solenoids, and updated hardware to meet industry standards.

NFPA-Compliant Safety Measures

Heavy gauge ductwork was strategically installed between the baghouse and the explosion isolation valve to meet the safety requirements outlined by NFPA.

Specialized Equipment Installation

Outcome

The aerospace manufacturing facility achieved full compliance with NFPA guidelines for combustible dust hazards.

Baghouse.com tailored solutions provided the client with a robust and compliant dust collection system, as well as improved overall efficiency and dust collection performance.

Conclusion

Baghouse.com expertise in dust collection systems and commitment to safety facilitated a seamless transition for the aerospace manufacturing client. By addressing DHA recommendations and implementing NFPA-compliant upgrades, the project not only met regulatory requirements but also significantly bolstered the safety and efficiency of the client’s dust collection processes.