In this design guide we have reviewed a relatively simple baghouse dust collection system with few variables. Even at this level it is still recommend to consult with an experienced dust collector OEM like Baghouse.com before making any equipment purchase. There may be additional factors to consider before determining the final sizing, design, construction and installation of a dust collection system.

Common Additional Considerations

- Recirculating air back into facility

- Balancing system with blast gates

- Combustible and toxic dust

- Filter styles

- Dust discharge (manual or automatic)

- Option for VRD fans

Recirculating Air Back Into The Facility

Recirculating air from the dust collector exhaust can prove practical in areas with cold climates to conserve heat. Make sure to include a ambient air return line to balance the airflows and prevent carbon monoxide poisoning. Additionally, any return duct needs to be sizes at least 2 inches larger than the main duct entrance and its SP added to the system total. Additionally, OSHA and other applicable safety regulatory bodies require any recirculated air to pass through a HEPA after filter.

Get help with your dust collection system now!

Combustible Dust and/or Toxic Compounds Hazards

Many types of dust, including many woods are toxic, so take special care to choose a filtering system that will provide optimal safety. Facilities that handle combustible dusts must take special precautions to avoid potentially serious safety hazards from forming within their dust collection system. The National Fire Code issued by the NFPA (National Fire Protection Agency), OSHA combustible dust emphasis program, and the OSHA General Duty Clause and many other similar local and state regulations now require a combination of explosion/fire prevention and/or protection devices for any dust collection system handling combustible dusts. Prevention devices include spark arrestors, abort gates, high-speed sprinklers, inert gas or injection systems, and more. Protection devices include explosion vents, high-speed sprinklers and dry extinguishing injection systems. Fire experts should be consulted for any system potentially handling combustible dusts.

Filter Styles

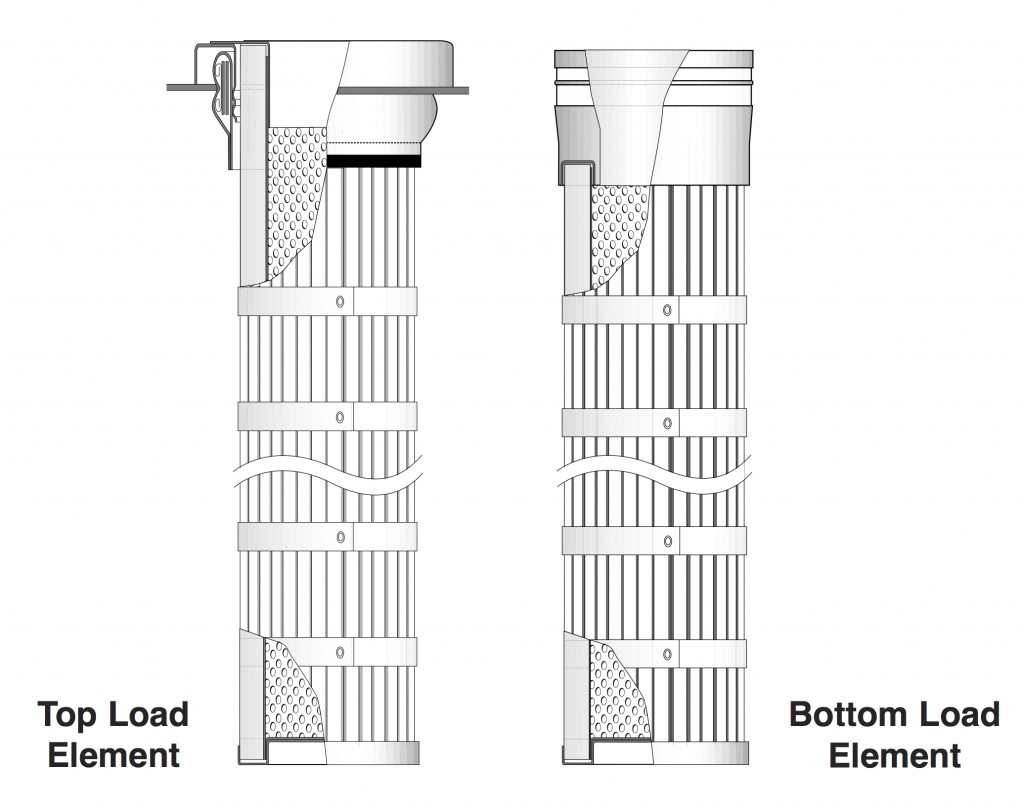

New filter styles such as pleated filter elements can improve operation, reliability and collection efficiency while also lower operating costs (less compressed air to clean, last longer) compared to traditional bag and cage technology. They also allow for much smaller units (thus cheaper to build) while still having better air to cloth ratios compared to bags since they also provide more filter cloth in a smaller area.

Bags, cartridges or pleated filter elements are three common filter styles used in baghouse dust collectors. Cartridges are rarely used in new systems except for a handful of OEMs due to high cost and difficulty sourcing replacements. Bags and cages are the most versatile being able to work in the widest range of applications including temperatures up to 500F. In newer systems, pleated filter elements (sometimes called pleated filters) provide a much larger filter cloth area in a smaller space compared to bags (usually 3 times as much filter in half the space). They are widely manufactured and are only marginally more expensive than bag and cages. In addition, they provide superior performance, require less cleaning energy (i.e. compressed air) and provide less pressure drop over a longer service life. And due to their smaller size, collector units can be made smaller. (See our case study showing benefits of converting from bag/cage technology to pleated filter elements)

Best Practices to Increase efficiency and Reduce Size

Try to capture dust as close as possible to source to reduce size requirements. More directed venting better solution than venting large area as volumes increase rapidly when venting entire spaces e.g. Venting one machine at 600 CFM = 6 bag unit vs. venting entire room of 30’ x 30’ x 10’ = 9,000 cubic feet of air = 125 bag unit @ 3:1 ratio Oversizing for future expansion Good idea to size in additional 10% capacity for later. Minimal added costs upfront to add additional capacity, resizing later much more expensive (10:1 ratio roughly)

Balancing System Using Blast Gates

Blast gates should be installed on all branch lines to maintain system balance. Their proper use should also be part of regular training for dust collector operation.

Clean Out Traps

If your system has areas where long slivers of material could possibly hang-up and cause a clog, install a clean-out near that area.

Determining Required Capacity For Secondary Sources

After adding all primary lines together determine how much extra capacity you want to install for secondary lines. If secondary branches are run sparingly then its possible to not include them in the calculation. When they need to be used you can divert some of the capacity from the primary branches (by shutting them down and blocking those ducts using a damper valve). Be realistic when calculating your needs and size appropriately.

Consider Variable Frequency Drive (VFD) Fans

VFD fans allow for more control over system performance and potential energy savings when loads constantly change.

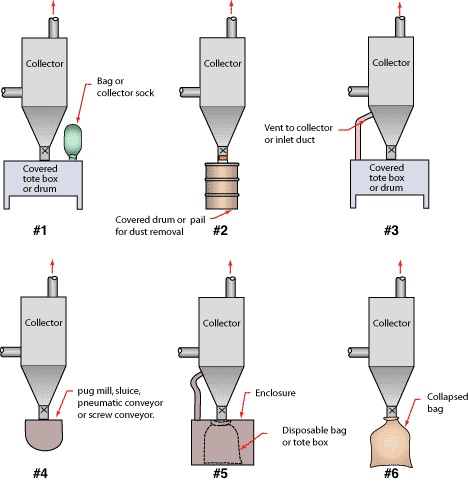

Dust Discharge Options

The most basic discharge is a manual slide gate, that is activated manually by personnel. If dust loads are light or the system is infrequently used this may be the most economical option. However, failure to keep the baghouse hopper clean and result in major operational problems and damage the filters. Another option is for a rotary airlock that automatically cleans the hopper. This eliminates the need for a technician to manually clean the hopper, but comes at a price tag in the $2,000 – $3,000 range.

Ready To Size Your Dust Collection System?

Thank you for reading our online guide to sizing your dust collection system. After considering this information should be able to estimate what size dust collection system your facility needs. With this information in hand you can begin the bidding process for your new system. Baghouse.com experts are ready to help if you have any questions. Please feel free to call at (702) 848-3990, contact us via our online form, or visit our resources section for more helpful dust collector information.

Need Help Designing Your Baghouse System?

Looking for help designing your dust collection system? Let our us use our 40+ years of expertise to help you select the right system for your application.