Yes, there is a difference between the two. One is used to increase collection efficiency and one is used primarily for protecting the filter bags from chemical attack.

What Are PTFE Membrane Filter Bags?

PTFE membrane is a thin layer of PTFE laminated to the surface of a filter bag. It captures dust on the surface of the filter and easily releases the dust when pulsed.

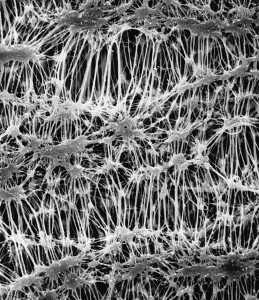

PTFE membrane is semi-porous layer of PTFE bonded to the surface of a filter. This membrane acts at a permanent dustcake, capturing incoming dust particles (i.e. particulate matter or PM 2.5) on the surface of the filter (surface filtration) as opposed to normal filters that require a thick layer of dust buildup (dustcake) to actually reach peak efficiency. This means that PTFE membrane bags can operate at peak collection efficiency from the moment they are installed, and do not need to be precoated. Overtime, the membrane also works against the dust penetrating deep into the depth of the filter fabric, which is the cause of filter blinding. For this reason, PTFE membrane bags often last considerably longer than standard filter bags and have a more consistent differential pressure over time.

PTFE Baghouse filters with PTFE membrane have the highest collection efficiency of all filters in production today. Bags using membrane technology can collect particulate matter down to 2.5 microns in size at over 99.99% efficiency. (In laboratory testing one OEM’s PTFE filters had 0.00% detectable emissions in the test rig). For this reason, in the applications with very tight emissions requirements, PTFE membrane filters are the standard.

Membrane bags are not recommended for a few limited applications, usually involving oils and hydrocarbons are these can close off the pores of the membrane and cause the filter to plug up.

What Are Filter Bags with PTFE Finish or Treatment?

PTFE membrane or PTFE finish can be applied to a baghouse filter made from any fabric, such as fiberglass, polyester, or aramid (Nomex). It can even be used with pleated filters or cartridges.

In this use of PTFE, rather than creating a surface layer or membrane on top of the filter, the filter fabric is coated in a bath or spray of liquid polytetrafluoroethylene (PTFE) resin. This is done to protect the filter. The treatment improves the flex life, heat and chemical resistance and dust release from the fabric. This increases the service life and efficiency of the filters. PTFE finish is commonly used in applications with corrosive chemical compounds, sticky dusts, or high moisture contents.

Would you like to learn how PTFE membrane filter bags can improve your dust collector operation and save you money? Contact us today to find out more!