Accurate differential pressure readings are essential for efficient baghouse operation. This article outlines the importace of baghouse differential pressure and what baghouse problems it can be used to diagnose.

By Dominick DalSanto

Baghouse Technology Expert and Sales Director

Baghouse.com

Baghouse Differential Pressure – Why Important?

Within a baghouse a number of factors must be controlled to ensure the efficient operation of the system at all times. Of these, the most important variable to control is the system differential pressure. This measurement is the key indicator of how the baghouse is operating and the most important factor to consider when diagnosing and troubleshooting issues with the baghouse system.

Over time more and more dirt will penetrate deep into the fibers of a bag being harder to remove. When this happens the bags become blinded or are unable to be adequately cleaned. This causes massive differential pressure increases.

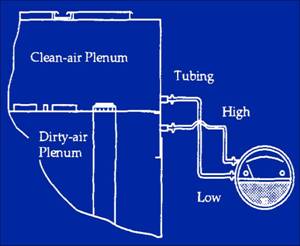

Differential pressure (also known as pressure drop or Delta-P) is the difference in pressure between the dirty-air side of the baghouse and the clean-air side. As in the incoming air is pulled through the filter media (i.e. filter bags) vacuum is lost, resulting in the air entering the baghouse having a weaker vacuum than the air exiting the baghouse. For example, let’s say that the system fan is pulling 10″ w.g* of vacuum pressure. When the dirty air comes into the baghouse the pressure is at 3.5″ w.g.* of vacuum, but after entering into the baghouse and passing through the filters the pressure rises to 10″ w.g.. This means the pressure drop across the baghouse is 6.5″ w.g. (Note: This example assumes a clean-air side fan or negative pressure system)

Differential pressure readings are used to determine a number of things about the operation of a baghouse system, such as filter bag condition, and structural problems with the unit, (airlock and conveying system condition and door seals condition among other things). Furthermore, a high system differential pressure usually indicates that the system is not running efficiently and therefore is incurring higher operating costs than it should under optimal circumstances. The following problems can be diagnosed from observing the system differential pressure:

Filter Bag Condition

- Bags are blinded off

- Dirty bags will become more resistant to airflow thus causing the force to push the air through them to rise.

- Bags have holes in them

- This will create a path of less resistance for the air to flow through leading to lower pressure drop

- Bags are not installed properly

- See above

Structural and Sealing Issues

- Leaks within the structure

- Common leak areas include airlocks, welds, joints (especially panelized construction units), and door seals

- Airlock leaks

- Common around flaps,rotars, gaskets and connection points.

- Conveying system leaks

- Common at connection point to hopper/airlock, holes in ductwork structure, etc.

- Doors and hatch sealing

- Gaskets on all doors and hatches, including viewports. Also includes making sure all doors have sufficient fasteners (i.e. bolts) to secure the door/hatch securely to form a tight seal.

Why High Differential Pressure Means Higher Operating Costs

Controlling your baghouse differential pressure is required to get the maximum performance and efficiency from your system. If your system is running at a high differential pressure it will inevitably cost more to operate, have lower performance and experience more downtime. High DP means the system fan needs to work harder to pull the same amount of airflow throughout the system. IF DP starts to rise above the recommended levels, maintaining the same level of draft (i.e. suction) at all of the systems pickup points will prove difficult. This will lead to much higher energy costs to run the system fan at high speed and can if over taxed lead to premature fan/motor failure. If the system fan is not adjusted to compensate for the higher differential pressure, the system will lose draft at all of its pickup points. This will mean less performance from your system and inescapably cause problems for your facility process whatever it maybe, especially so for certain industries that are more dependent on the dust collection system as part of the process such as cement, powdered metals, chemical processing, etc. In the end, this will result in the process being shutdown or even a shutdown of parts or the entire facility until the system is running again.

Conclusion

Clearly, it is of vital importance for maintenance staff and operators to keep close watch on dust collection system differential pressure. If system DP is higher than recommended it can be a indicator of several potentially serious issues, ranging from blinded bags, to holes in the structure to poor seals, etc. Accordingly, obtaining accurate differential pressure readings is vital to have an accurate picture of what is going on within your baghouse system. But what can you do if your equipment is giving you suspicious or even false readings? How can you determine when your DP gauges and controls are sending false readings? These questions will be in the following article in the series: Baghouse Differential Pressure – How To Troubleshoot False Readings

Footnotes:

* “w.g. stands for inches of water gauge, that is vacuum pressure as measured in inches of water (sometimes mercury) as in a magnehelic gauge.

| Dominick DalSanto is an Author & Environmental Technologies Expert, specializing in Dust Collection Systems. With nearly a decade of hands-on working experience in the industry, Dominick’s knowledge of the industry goes beyond a mere classroom education. He is currently serving as Sales Director at Baghouse.com. His articles have been published not only on Baghouse.com , but also on other industry related blogs and sites. In his spare time, Dominick writes about travel and life abroad for various travel sites and blogs.

Baghouse.com Corp